Equipment List

Samax Precision Inc. continuously invests in the most advanced machining and inspection equipment available, enabling us to maintain extreme accuracy and consistency.

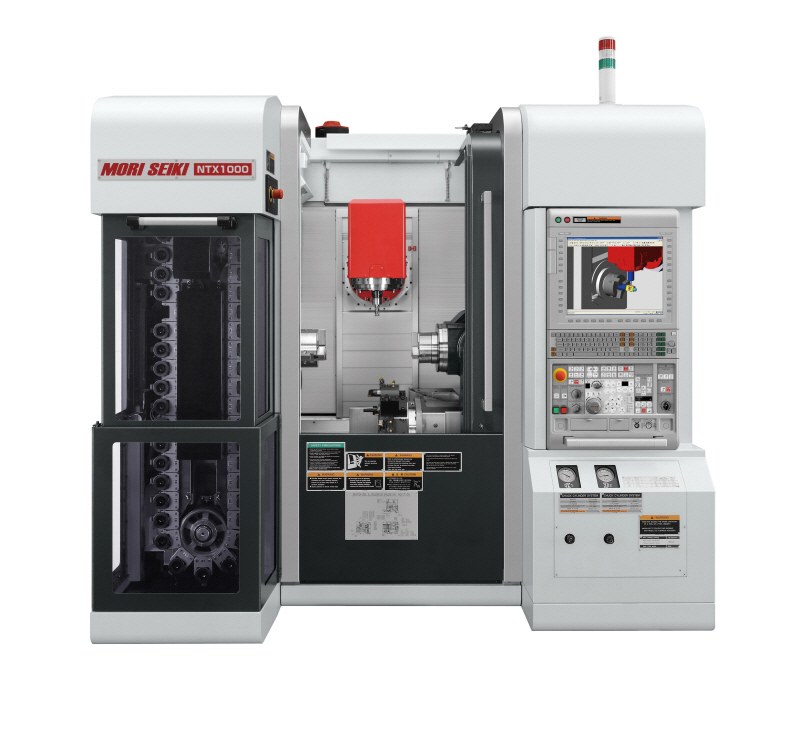

5-axis MillTurn

Mori Seiki NTX-1000SZ – Full simultaneous 5-axis MillTurn with LNS Quick Load Servo 65 Barfeed and Cooljet 1000 psi high-pressure coolant

CNC Lathe

Doosan 220 LMS – 13″ diameter x 20″ long (maximum machining capacity, with milling function)

Doosan 220 A – 13″ diameter x 13″ long (maximum machining capacity)

Akira Seiki Sl-25 – 12″ diameter x 15″ long (maximum machining capacity)

Nakamura-Tome SC-250 – 14″ diameter x 20″ long (maximum machining capacity, with milling function)

Doosan Puma 2100SY – 15″ diameter x 20″ long (maximum machining capacity, with milling function, with “Y” axis)

Mori Seiki Manual Lathe

CNC Vertical/Horizontal Mill

Niigata SPN40 Horizontal Mill – Automated 6 pallet system (maximum machining capacity 24″ x 23″x 26″)

Akira Seiki SV600 Vertical Mill – (maximum machining capacity 24″ x 20″ x 20″)

Akira Seiki SV1000 Vertical Mill – (maximum machining capacity 40″ x 20″ x 20″)

Akira Seiki SV1700 Vertical Mill – (maximum machining capacity 60″ x 30″ x 30″)

Akira Seiki Performa V4 Vertical Mill – (maximum machining capacity 50″ x 20″ x 20″)

DMG/MORI NHX4000_M703BM-HMC – (maximum machining capacity 22″ x 22″ x 26″)

(2)DMG/MORI Duravertical 5100_FDiMD – (maximum machining capacity 41.3″ x 20.9″ x 20.1″)

Hitachi Seiki VS50 Vertical Mill – (maximum machining capacity 40″ x 20″ x 20″)

(2) J Head Manual Mills with DRO

Laser Welder

LaserStar 1900 XL Series (automation chamber dimensions 28” x 19” x 12.9”)

Preview Images for laser welding…

Inspection Tools

COORD3 Hera 7.10.7 Automatic CMM with Renishaw PH20 Infinite Indexing Probe Head with CMM Manager software with CAD package (maximum part measuring 27.5″ x 39″ x 25.5″)

LK Metrology System G90c Automatic CMM with Renishaw PH10/TP200 probe with CMM Manager software with CAD package (maximum part measuring 32″ x 28″ x 24″)

(2)Brown & Sharpe Microval 454 3B with CMM Manager software with CAD package (maximum part measuring 18″ x 20″ x 16″)

Scherr Tumico 12″ x 6″ Optical Comparator with M2E DRO Touchscreen and Edge Sensing with MetLogix M2 Software

Scherr Tumico 8″ x 6″ Optical Comparator with Quadra-Chek 2000 and Edge Sensing

MicroView 311UC Vision System

Parlec Tool Presetter

Software

Mastercam 2021 (multi-axis CAM software)

Esprit 2020 (multi-axis CAM software)

Solidworks 2020 (3D CAD software)

JobBoss (MRP system)

Unipoint (TQM)

CMM Manager (CMM inspection software)

Materials

Samax Precision’s experienced machinists have the skills and experience to work with a broad range of materials.

(Click material label to view list)

Aluminum

2024

6061

5052

7050

7075

MIC 6

Stainless Steel

303

304

304L

316

316L

410

416

420

440

13-8

15-5

17-4

17-7

Nitronic 60

Aircraft Alloys - Steel

4140

4620

Nickel/Super Alloys

Nickel 200

Nickel 400

Nickel 625

Kovar

MP35

Hastelloy

Monel

Invar

Plastics

Delrin

Radel (PPSU - Polyphenylsulfone)

Glass filled AF

Acetal

Nylon

Torlon

Vespel

Flourogold

Telfon _(PTFE - Polyetrafluoroethylene)

ABS

Kel-F (PCTFE - Polychlorotrifluoroethylene)

Acrylic

PVC

Rexolite

FEP (Fluorinated Ethylene Propylene Polycarbonate)

PEEK (Polyetheretherketone)

Ultem (PEI - Polyetherinide)

Polycarbonate

Rulon

Turcite

UHMW

Copper Alloys

C100 Series (Coppers)

C200 Series (Brasses)

C300 Series (Leaded Brasses)

C400 Series (Tin Brasses)

C500 Series (Phosphor Bronzes)

C600 Series (Bronzes)

C700 Series (Nickel Silvers)

Titanium

Hi-Temperature Alloys

Inconel

Moly (molybdenum)

Tungsten

Monel

Hastelloy

Carbon Steel

1010

1018

12L14

A36

A515

A516